DEFORM-3D is a powerful process simulation system designed to analyze complex, three-dimensional (3D) metal forming processes. It is a practical and efficient tool for the prediction of metal flow, heat transfer and more. Manufacturing operations can be simulated on the computer, avoiding much of the cost and delay of shop trials. Typical applications include hot forging (closed and open die), warm and cold forming, cogging, rolling, drawing, extrusion, heating, machining and mechanical joining.

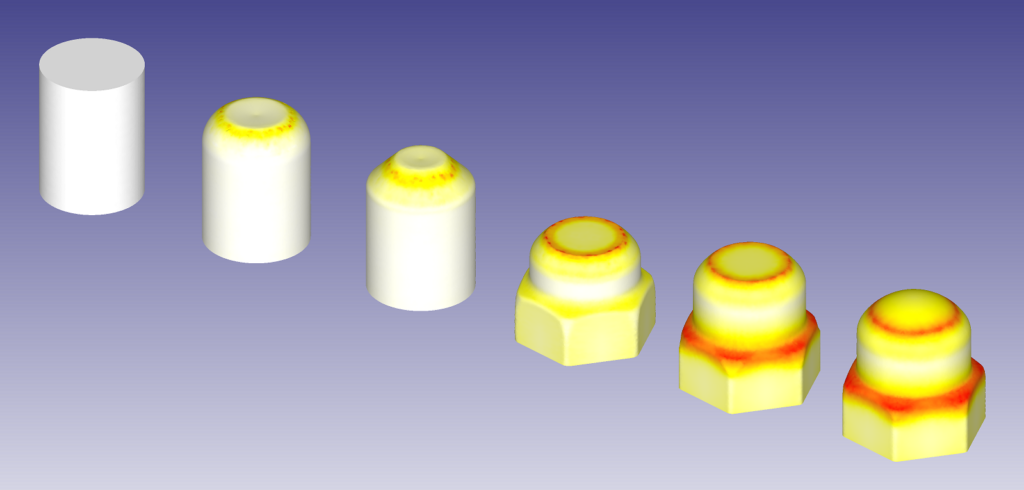

Based on the finite element method (FEM), DEFORM has proven to be an accurate and robust solution in industrial applications for over three decades. The simulation engine is capable of predicting large deformation metal flow with high precision. An advanced mesh generator automatically applies an adaptive, optimized mesh to parts and tooling. This captures important model detail while minimizing the simulation time. User-defined meshing tools allow advanced users to customize the mesh to their requirements.

While DEFORM-3D provides sophisticated analysis capabilities, the graphical user interface is intuitive and easy to learn. A ‘state of the art’ multiple operation interface provides guided data input for a wide range of processes types. Individual operations can be combined into process sequences that can be run one-by-one or sequentially. This is the foundation for a comprehensive modeling system that can incorporate forming, material modeling, design of experiments (DOE) and optimization.

Scientific Forming Technologies Corporation (SFTC) staff has a unique combination of industrial, academic and software experience. This diverse background enables SFTC to provide unparalleled training and technical support. Our support staff is personally committed to the success of each and every DEFORM user.

Product Specifications

- Deformation and heat transfer are automatically calculated in an integrated simulation environment.

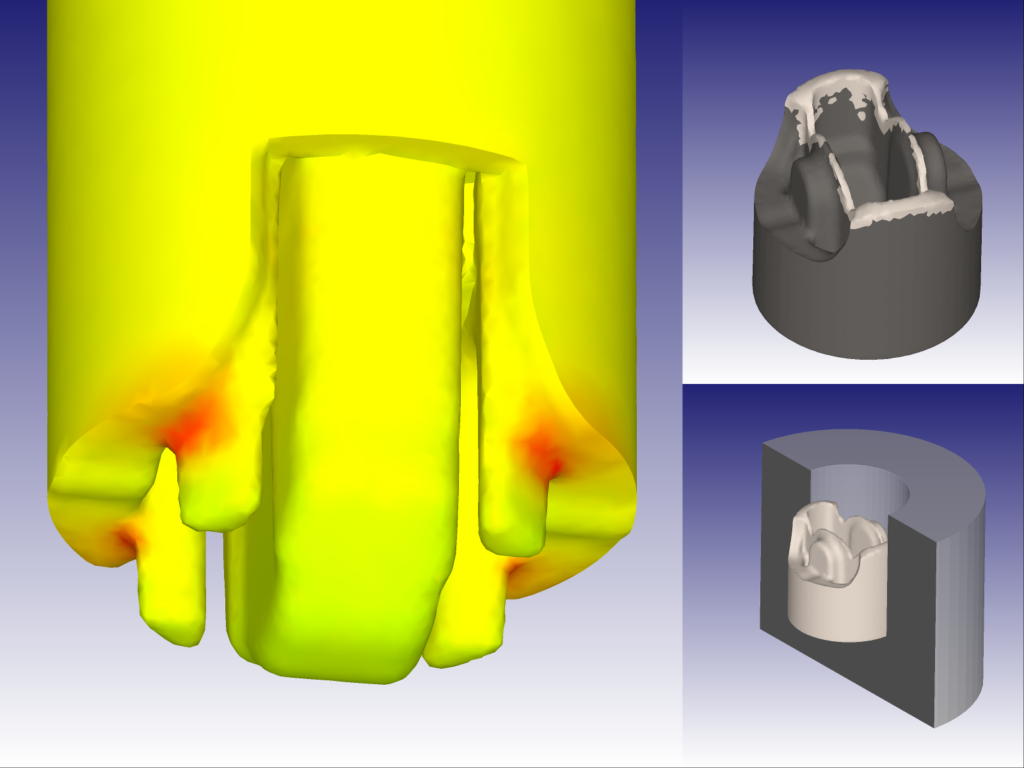

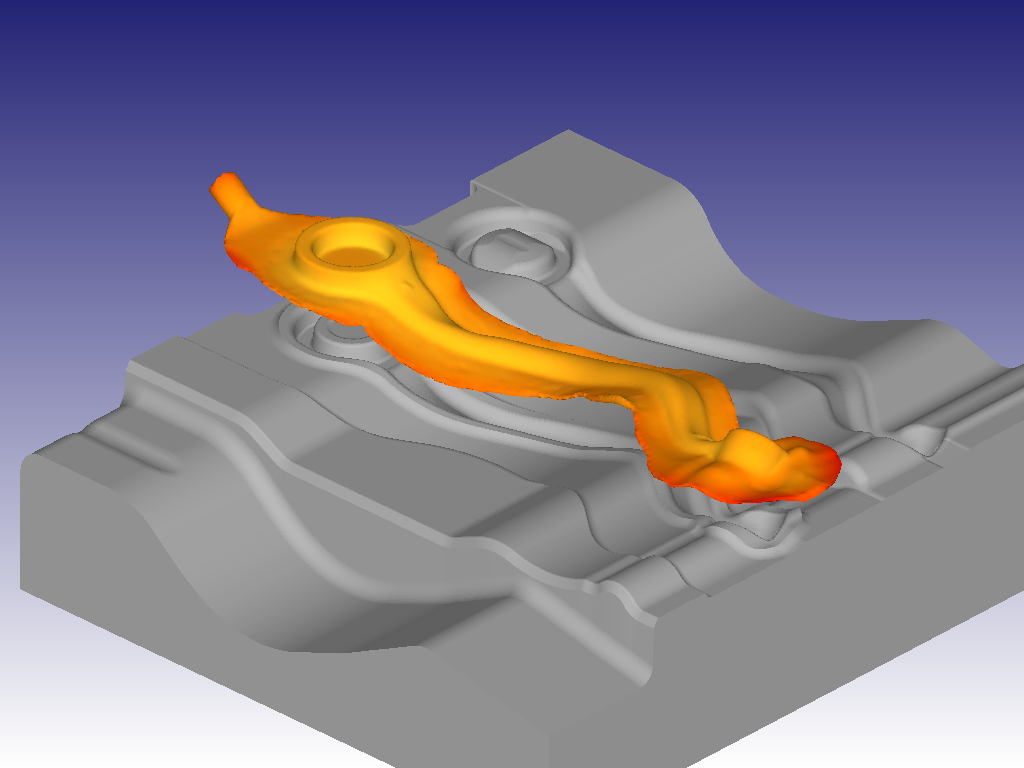

- Three-dimensional simulation allows the analysis of complex geometry, which cannot be accurately modeled using 2D.

- Fully automatic optimized remeshing is performed during simulation.

- The material models include elastic, rigid-plastic, thermal elasto-plastic, thermal rigid-viscoplastic, porous and rigid.

- Multiple deforming body simulation allows for coupled tool stress analysis.

- The FEM engine predicts fracture based on damage models.

- A machining specific pre-processor is available to simplify problem setup in DEFORM-3D.

- DEFORM-2D can be used to simulate machining, using a plane strain approximation.