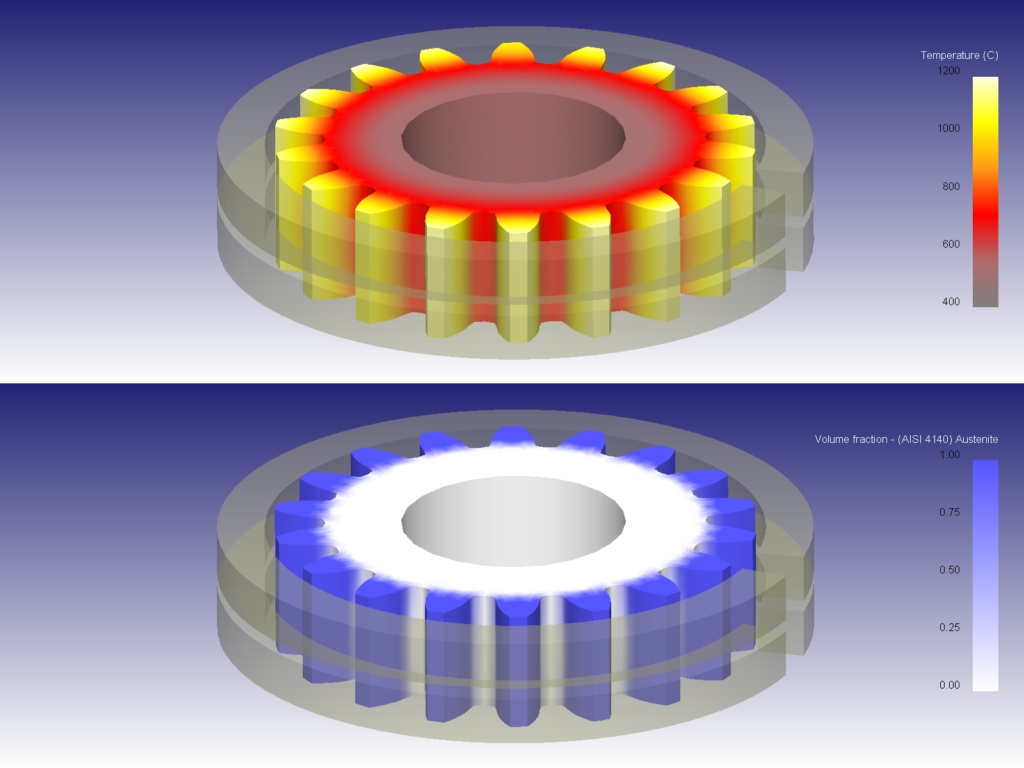

The Microstructure Module expands the capabilities of DEFORM-2D and DEFORM-3D to include a wide range of microstructure and mechanical property information. Two approaches for modeling microstructure evolution during thermo-mechanical processing are implemented in DEFORM.

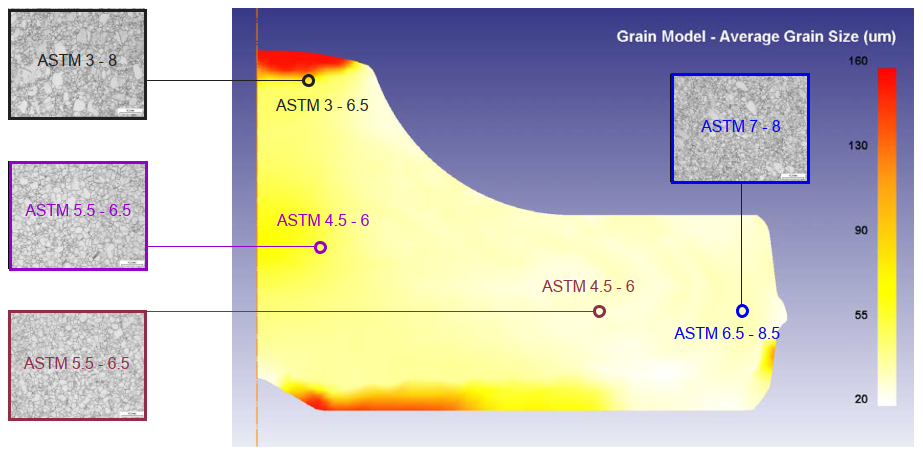

The Johnson-Mehl-Avrami (JMAK) is an empirical method. JMAK models are used to predict average grain size and percent recrystallization throughout a part. This method has been used in aerospace industry to predict grain size in nickel-based superalloys for years. Dynamic, metadynamic, static recrystallization kinetics and grain growth are modeled. JMAK microstructure model data are available within DEFORM for a variety of materials.

Microstructure modeling is used to predict residual stress and a range of mechanical properties. Scientific Forming Technologies Corp. is the leader in the development and application of microstructure modeling for research and industrial applications

Product Specifications

- Model outputs for the Microstructure Module include grain size, percentage recrystallization and phase volume fraction. rain orientation, percipitate size and texture.

- Standard DEFORM-HT outputs such as distortion and residual stress are also available.

Licensing Options

- The Microstructure Module can be added to a DEFORM-2D or DEFORM-3D license to enable microstructure evolution during thermo-mechanical processing.