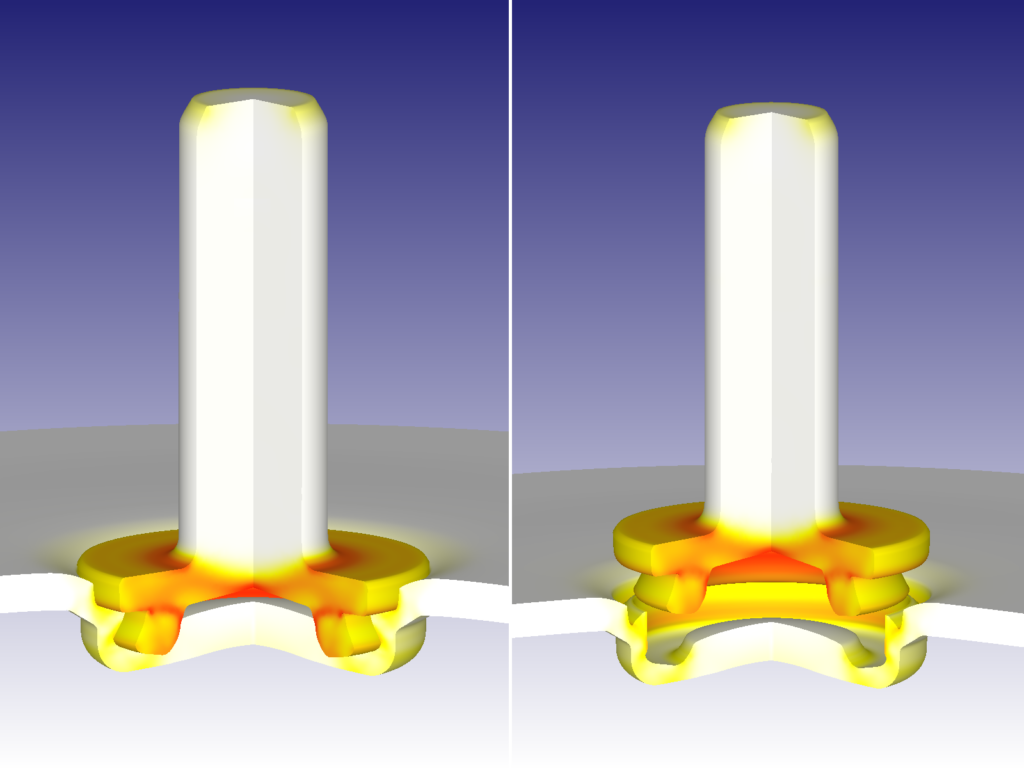

DEFORM -2D is a Finite Element Method (FEM) based process simulation system designed to analyze two-dimensional (2D) behavior in complex metal forming processes. It provides vital information about material and thermal flow during the forming process, facilitating the design of products and required tooling. DEFORM-2D has been used by companies worldwide to analyze forging, extrusion, drawing, heading, upsetting and many other metal forming processes.

DEFORM-2D offers state-of-the-art process simulation technology. Its powerful simulation engine is capable of analyzing complex interactions of multiple deforming objects with different material properties. This allows realistic and accurate modeling of metal forming processes within production environments. Its sophisticated mesh generator automatically creates an optimized mesh system whenever necessary. By considering the solution behavior, the mesh generator creates finer elements in regions where greater solution accuracy is required. This reduces the overall problem size and computing requirements. The flexible and powerful graphical user interface makes the preparation of input data and examination of result data very easy to accomplish

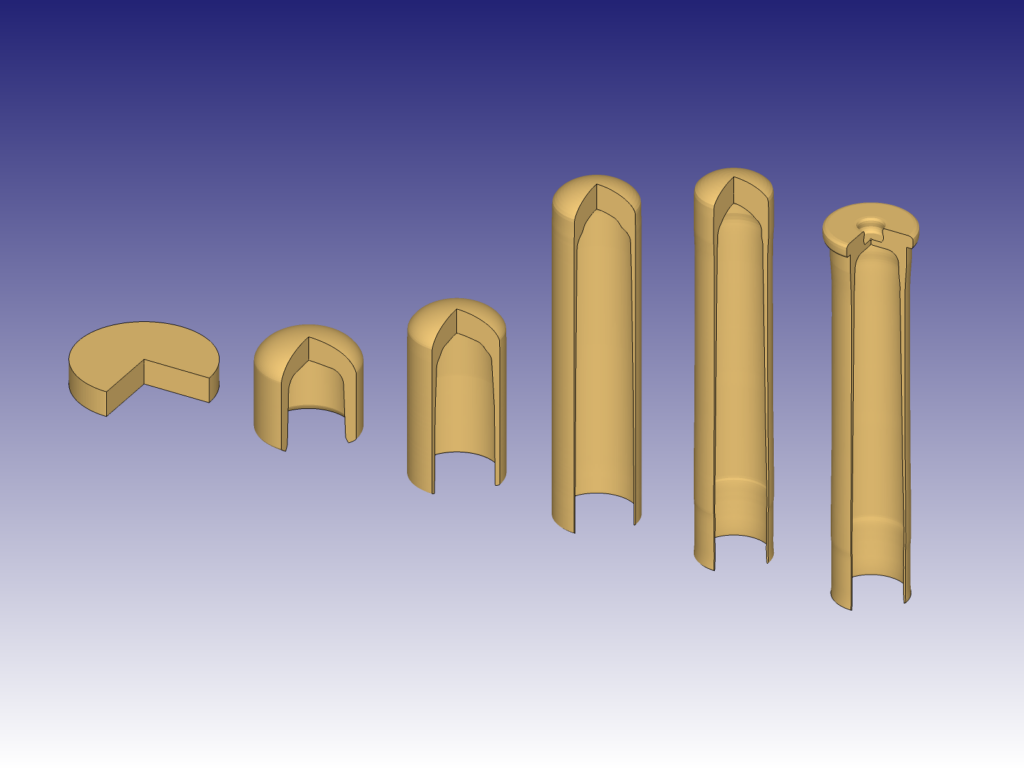

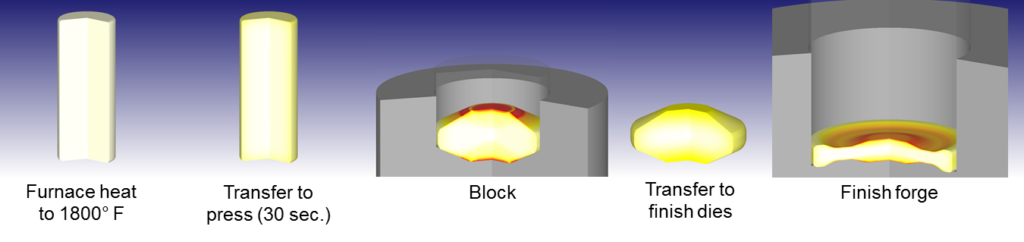

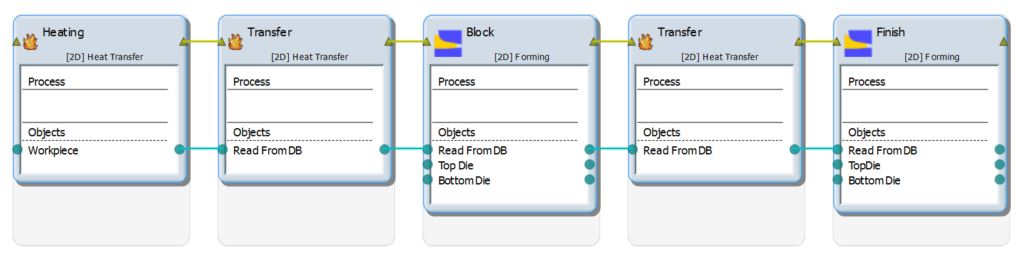

DEFORM-2D employs core technologies from decades of research and production application at leading companies worldwide. A ‘state of the art’ multiple operation interface provides guided data input for a wide range of process types. Individual operations can be combined into process sequences that can be run one-by-one or sequentially. This is the foundation for a comprehensive modeling system that can incorporate forming, material modeling, design of experiments (DOE) and optimization.

Scientific Forming Technologies Corporation (SFTC) staff has extensive manufacturing, academic and software-industry experience. This diverse background enables SFTC to provide unparalleled training and technical support to DEFORM users.

Product Specifications

- Deformation and heat transfer are calculated in an integrated simulation environment.

- Two-dimensional capabilities include axisymmetric, plane-strain and plane-stress simulations.

- Fully-automatic and optimized remeshing is performed during simulations.

- Forming equipment models are available for hydraulic presses, hammers, screw presses and mechanical presses.

- Material models include elastic, rigid-plastic, thermal elasto-plastic, thermal rigid-viscoplastic, porous and rigid types.

- Deformation, contour plots, load-stroke prediction, point tracking, FLOWNET and other features are available in the post-processor.

- Multiple deforming body capability allows the analysis of mechanical joining or coupled die stress.

- The FEM engine predicts fracture based on damage models.

- A self-contact boundary condition allows a simulation to continue after a lap or fold has formed.

- Multiple operation sequences run without user intervention.

- A machining distortion ‘template’ streamlines the calculation of distortion after material removal.