DEFORM-HT is a powerful stand-alone finite element modeling system for simulating heat treatment processes. The system predicts thermal, mechanical and metallurgical responses of parts during heat treatment. Heat treat distortion, quench cracking and residual stresses can be predicted. The system can also provide information on phase transformation and phase volume fraction.

A variety of materials, ranging from carbon steel and aluminum to titanium and nickel-based alloys, can be modeled. Typical heat treatment processes include:

- normalizing

- carburizing

- quenching

- aging

- austenizing

- solution treatments

- tempering

- stress relieving

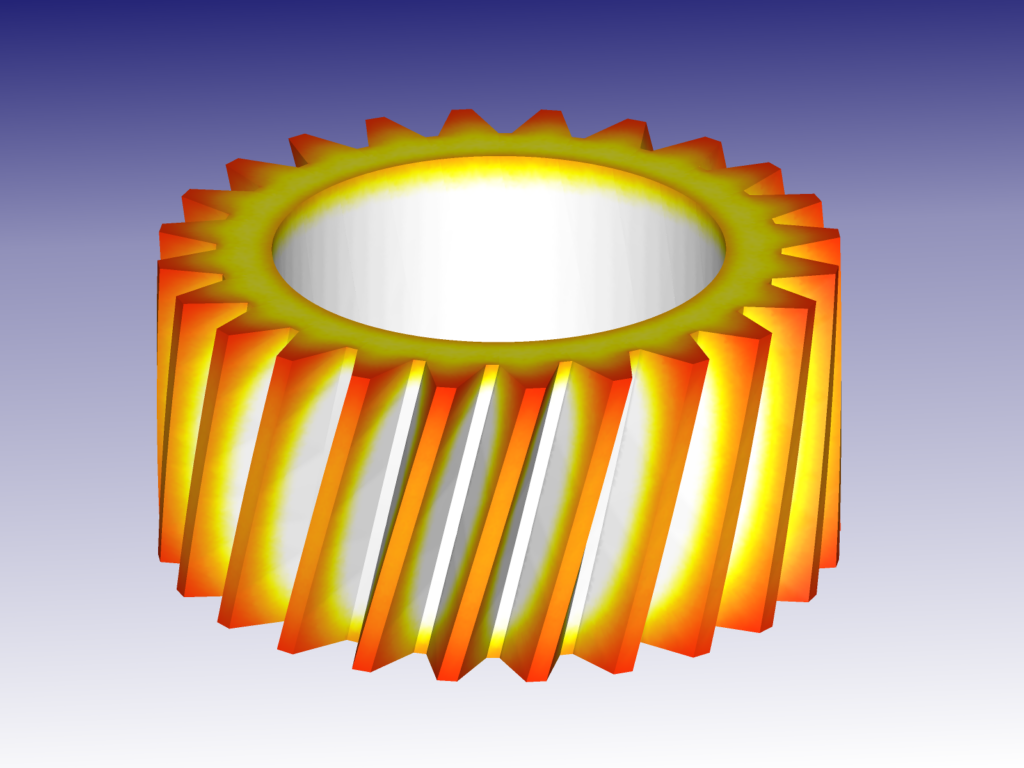

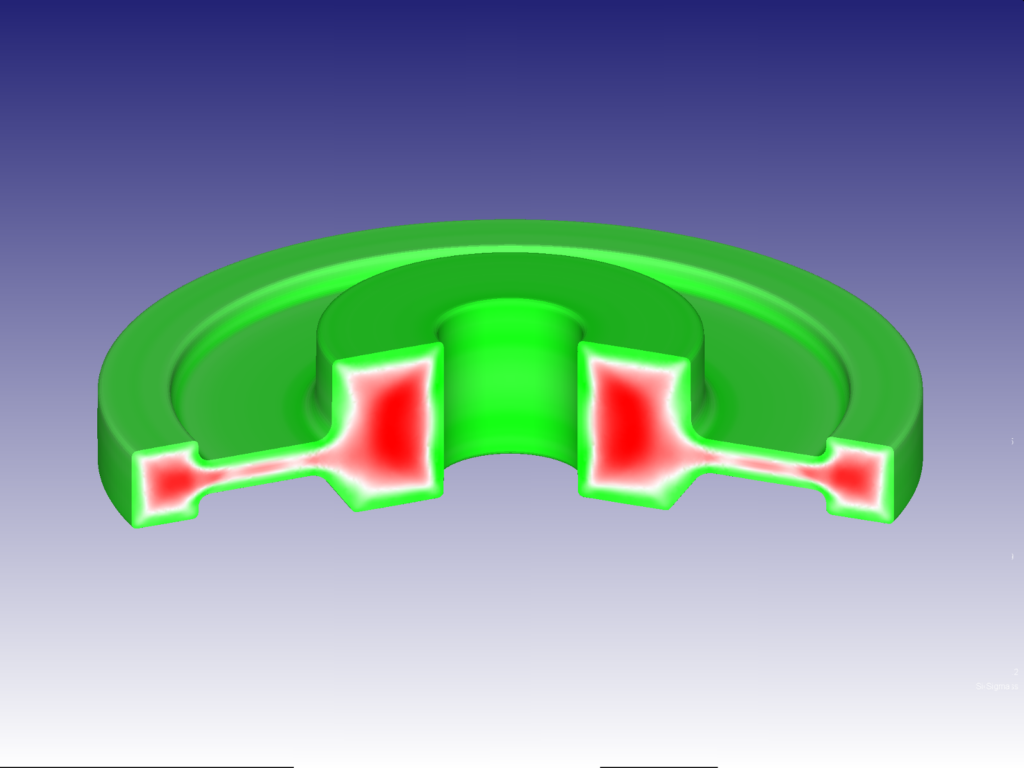

DEFORM-HT can analyze diffusion processes such as carburization, which provides a prediction of case depth. Phase transformation may be modeled using volume fractions. A high martensitic phase volume fraction (red) is shown on the gear at left. Residual stress response during and after heat treatment processes can also be predicted. Modeling of residual stress is important, since the stress field may significantly impact subsequent machining distortion and the life of a component in service. DEFORM is also capable of simulating stress relaxation and aging.

This powerful modeling tool provides critical information about the process variables required to control and optimize heat treatment processes. It provides the ability to visualize the microstructure, temperature and stress during heat treatment. This is simply not possible with experiments. It is possible to conduct sensitivity analysis without the time and cost of physical trials. DEFORM-HT is a tool that enables users to achieve an optimum balance of mechanical properties, while avoiding quench cracks and minimizing heat treat distortion and residual stresses.

Product Specifications

- DEFORM-HT is a stand-alone system to simulate heat treatment processes. DEFORM-HT2 uses a two-dimensional model for axisymmetric or plane strain applications. DEFORM-HT3 is used for complex three-dimensional applications.

- Model outputs include evolution of temperature, residual stress, distortion, phase volume fraction, case depth and hardness.

- Heat transfer, phase transformation and diffusion modules are coupled in an integrated simulation environment.

- A mixture rule is used to define various phase properties as a function of temperature and primary alloying element.

- Volume change due to phase transformation is accounted for in the model.

- Popular creep models are implemented to simulate the stress relaxation process.

- Induction and resistance heating capabilities are included with DEFORM-HT.