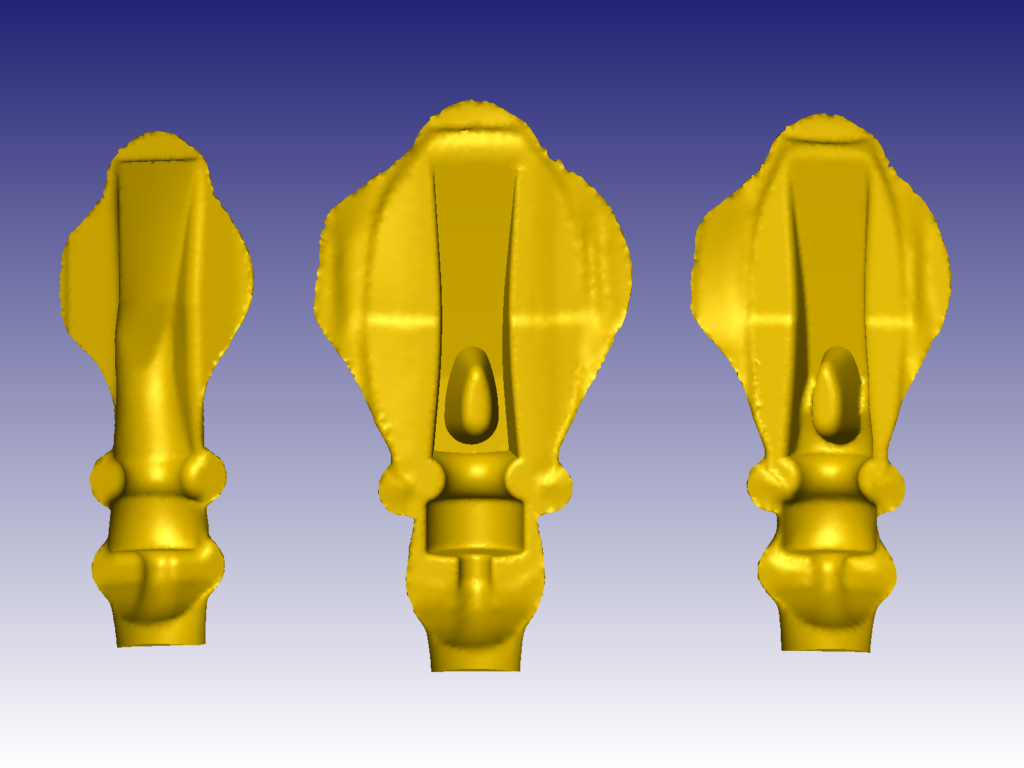

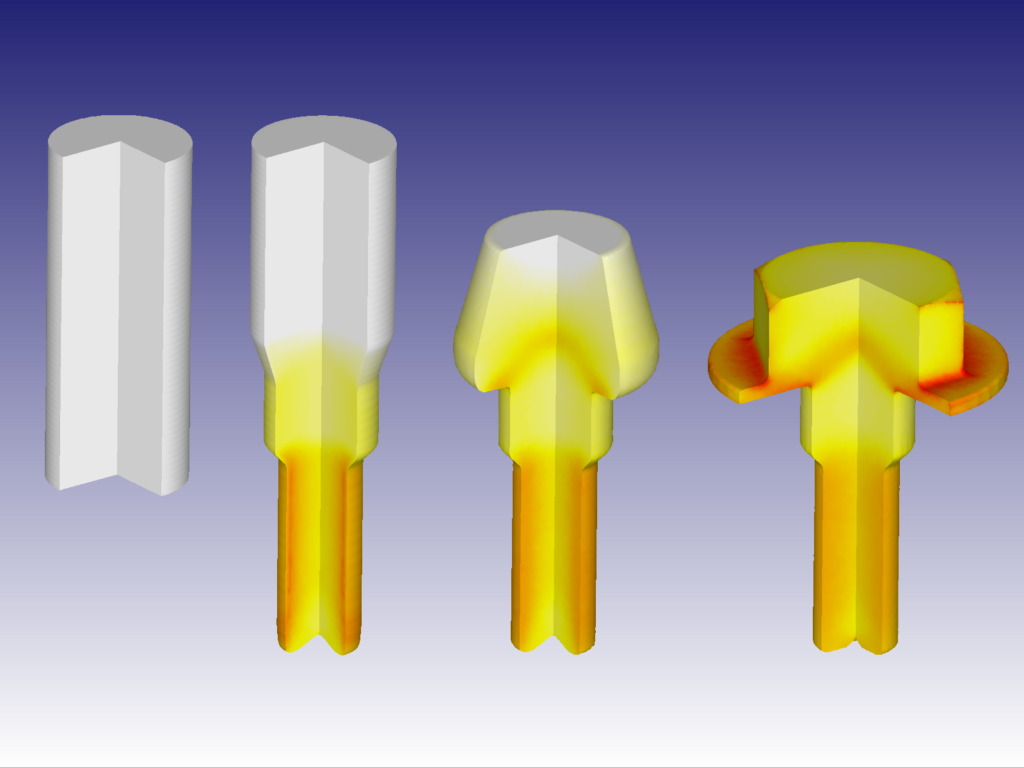

FORMING EXPRESS (3D) is a popular process simulation system designed to analyze three-dimensional (3D) material flow and heat transfer in metal forming processes. Applications include hot forging (closed and open die), warm and cold forming, drawing, extrusion and more. 3D simulation is needed to model complex shapes or defects such as buckling. FORMING EXPRESS is a practical and efficient tool to predict the outcome of metal forming operations without the cost and delay of shop trials.

Based on the finite-element method (FEM), DEFORM has proven to be an accurate and robust solution in industrial applications for more than three decades. The simulation engine is capable of predicting metal flow, loads and defects with great precision. The automatic mesh generator produces an optimized mesh with little user input. FEM settings are derived from the process details supplied by the user. FORMING EXPRESS shares the system architecture, mesh generator and FEM engine of DEFORM-3D, the advanced 3D process simulation system.

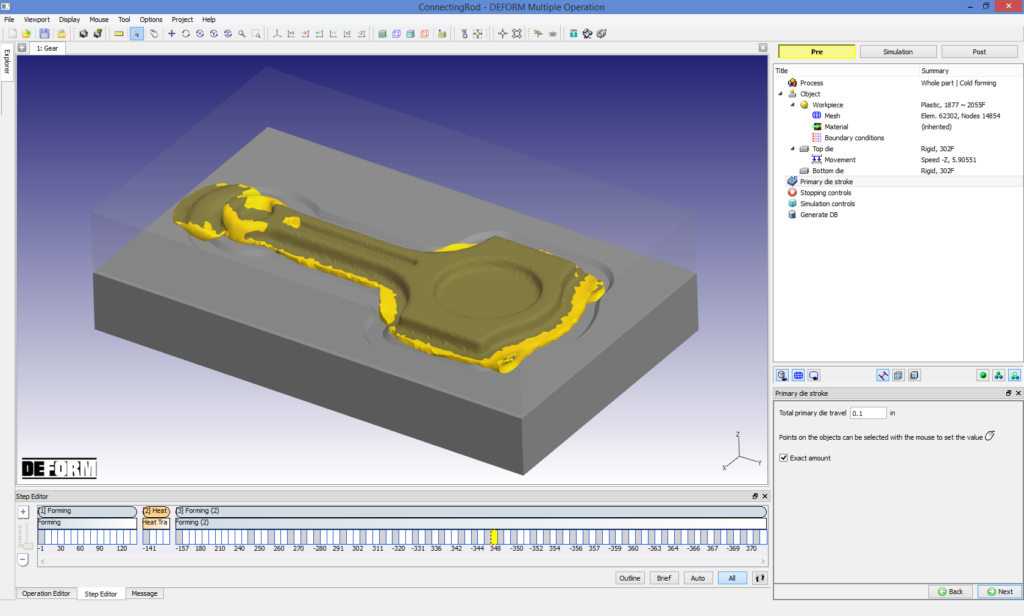

While FORMING EXPRESS provides sophisticated analysis capabilities, the graphical user interface is intuitive and easy to learn. A ‘state of the art’ multiple operation interface allows individual operations to be combined into process sequences that can be run one-by-one or sequentially. The system guides a user through data preparation, but also allows direct access to modify parameters or review results.

Scientific Forming Technologies Corporation (SFTC) staff has a unique combination of industrial, academic and software experience. This diverse background enables SFTC to provide unparalleled training and technical support. Our support staff is personally committed to the success of each and every DEFORM user.

Product Specifications

- Deformation and heat transfer are calculated in an integrated simulation environment.

- 3D simulation describes a wide range of complex geometries and behaviors.

- Planar symmetry is easily defined, when applicable.

- Automatic, adaptive remeshing is performed during simulations.

- Forming equipment models are available for hydraulic, screw and mechanical presses and hammers.

- Speed, load and sliding die (spring) controlled translational movements are also supported.

- Material models include rigid-plastic for cold forming, thermal rigid-viscoplastic for hot forging and elastic for die stress analysis.

- A wizard-based user interface allows for fast and efficient data preparation.

- Multiple operation sequences run without user intervention.

- Simulation results are analyzed via a powerful post-processor