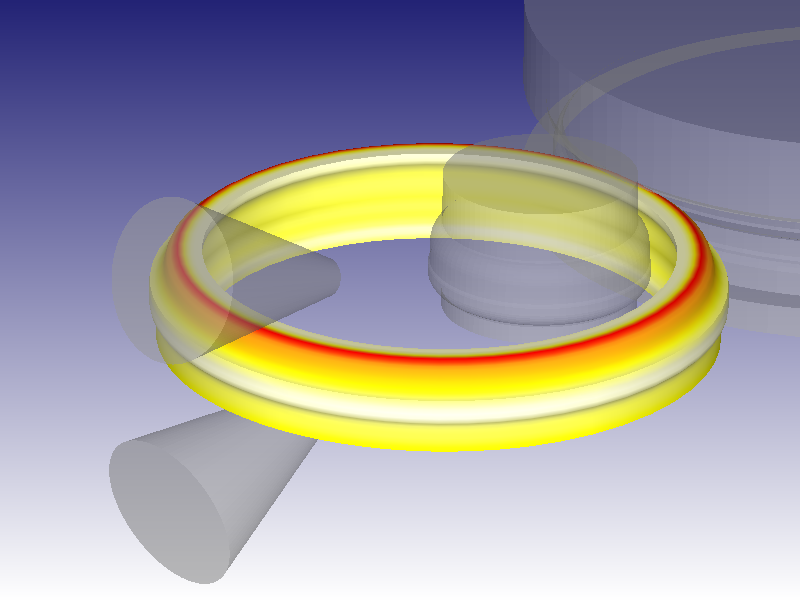

Ring Rolling has been one of the most computationally demanding applications in metal forming simulation. Traditional process simulation codes require days, weeks or months to analyze typical jobs. Even with extremely fast hardware, the ‘brute force’ methods employed by such codes are impractical.

Specialized ring rolling capabilities are available in DEFORM-RR and the Ring Rolling Module. The application-specific preprocessor streamlines the model setup procedure. The FEM engine is extremely efficient, as it was specifically designed for ring rolling. Simulations that previously took weeks now run in hours to days.

This ‘state of the art’ system utilizes an ALE solver with automated time stepping. The model uses brick (8 node) elements

and supports fully automatic adaptive remeshing. The updating and contact algorithms are optimized for ring rolling. The result is an accurate solution, without artificial constraints on the rotation axis.

DEFORM is the first code to deliver a ring rolling program capable of running on practical hardware in reasonable times. Test cases have been run with 15-20,000 brick elements running 25 to 75 revolutions in approximately an hour per revolution, on a single CPU PC!

Ring Rolling

- Ring Rolling simulation is available as a module that runs with DEFORM-3D.

- DEFORM-RR is a stand-alone version of the Ring Rolling program.

- The current isothermal implementation supports a workpiece, drive roll and mandrel.